- Extra thick partial coating made of light-yellow latex

- Palms made of cotton

- With safety inner sleeve

- Roughened surface for a good grip

- Application areas: Proven and advisable when handling abrasive and sharp-edged parts (cement stones, paving stones, construction steel, sheet metal etc.)

- Length: approx. 26 cm

Important: The assessment is not a legally binding statement about the actual application suitability. For thisplease refer to the respective EN standards with the test code of the various gloves here in the text of the details screen.

- good wet grip

- flexible and elastic

- waterproof

- for medium to heavy-duty work

Price

Packaging size

Available sizes

Glove application recommendation

Glove total length

Material / coating

Protection standard

Special properties

Extras

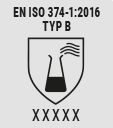

Full chemical protection TYP B

Full chemical protection gloves primarily aim to protect the hands against chemicals. They are assigned to the PSA Category III. Due to the infinite range of chemicals, there is no one specific glove that will offer protection against all liquids. Instead, the best product must be selected for the task at hand. Full chemical protection has a protection index of at least 2, i.e. a permeation time > 30 minutes for at least 3 of 12 statutory defined test chemicals. (Permeation = penetration on a molecular level).

TYPE B

Permeation performance at least level 2, >30 minutes against at least three chemicals in the list:

Testing Criteria:

A- Methanol

B- Acetone

C- Acetonitrite

D- Di-chloromethane

E- Carbon disulphide

F- Tuluol

G- Diethylamine

H- Tetrahydrofuran

I- Ethyl acetate

J- N-Heptane

K- Sodium hydroxide 40 %

L- Sulphuric acid 96 %

M- Nitric acid 65%

N- Acetic acid 99 %

O- Ammonium hydroxide 25 %

P- Hydrogen peroxide 30 %

S- Hydrofloric acid 40 %

T- Formaldehyde 37 %

Thermal risks

One faces a number of thermal risks at work. For the protection effect of the gloves it is important to differentiate between ambient heat or direct contact with hot objects. Risks are also involved when faced with extreme heat caused by fires, radiation etc.

Heat protection gloves should have wear resistance properties and also a certain level of cut resistance. The minimum wear and tear resistance according to EN 388 is specified for protection gloves of the EN 407.

Fire-resistant and heat-resistant protection gloves from Strauss offer day-to-day safety at work.

Testing Criteria:

Flammability: 0-4

Contact Heat Resistance: 0-4

Convective Heat Resistance: 0-4

Radiant Heat Resistance: 0-4

Resistance to small drops of molten metal: 0-4

Resistance to large quantities of molten metal: 0-4

The higher the number (shown with an X below the icon in the example), the better the test result.

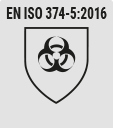

Microorganisms

It is usually assumed that protection gloves that withstand penetration in the test, offer effective protection against bacteria and fungi. However, because many viruses are much smaller than bacteria and fungi, these protection gloves may offer inadequate protection in practical fields.

A protection glove that is resistant to bacteria is a watertight glove that has a maximum AQL value of 1.5 in the permeability test. The AQL value (AQL = Acceptable Quality Level) reflects a given limit or the minimum quality requirement.

In general, the lower the AQL value, the better the quality of the protection gloves.

Protection against microorganisms:

Gloves that protect against bacteria and fungi. Not tested against viruses.

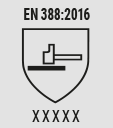

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

- good wet grip

- flexible and elastic

- waterproof

- for medium to heavy-duty work

- good wet grip

- flexible and elastic

- waterproof

- for medium to heavy-duty work

- good wet grip

- flexible and elastic

- waterproof

- for medium to heavy-duty work