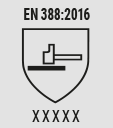

- EN 388:2016, Mechanical risks, 4144X

- Strong split leather quality

- Application areas: Highly suitable for general construction, warehousing and transportation work

- Length: approx. 26 cm

- Size 10

Important: The assessment is not a legally binding statement about the actual application suitability. For thisplease refer to the respective EN standards with the test code of the various gloves here in the text of the details screen.

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

- Wear-resistant

- Sturdy and tear-proof

- Good mechanical protection

- For heavy-duty work

In the case of split leather, the upper grain layer is removed by splitting. This middle layer of skin is distinguished by its rough velour-like texture. Split leather gloves are resistant to heat and the cold, they are wear-resistant and offer good protection of the hands.

Price

Available sizes

Glove application recommendation

Glove total length

Material / coating

Protection standard

Special properties

Extras

Grain leather, also called full leather, is the upper most valuable layer of the leather. It is the former fur side of the skin and can be recognised by its natural smooth surface that makes it resistant to oils, grease and wet. It is also very strong and supple. This means that the sturdy, very wear-resistant grain leather is ideal wherever dexterity is required. Gloves made of upholstery leather are also produced from grain leather.

- Wear-resistant

- Sturdy and tear-proof

- Good mechanical protection

- For heavy-duty work

Thermal risks

One faces a number of thermal risks at work. For the protection effect of the gloves it is important to differentiate between ambient heat or direct contact with hot objects. Risks are also involved when faced with extreme heat caused by fires, radiation etc.

Heat protection gloves should have wear resistance properties and also a certain level of cut resistance. The minimum wear and tear resistance according to EN 388 is specified for protection gloves of the EN 407.

Fire-resistant and heat-resistant protection gloves from Engelbert Strauss offer day-to-day safety at work.

Testing Criteria:

Flammability: 0-4

Contact Heat Resistance: 0-4

Convective Heat Resistance: 0-4

Radiant Heat Resistance: 0-4

Resistance to small drops of molten metal: 0-4

Resistance to large quantities of molten metal: 0-4

The higher the number (shown with an X below the icon in the example), the better the test result.

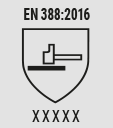

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

- Wear-resistant

- Sturdy and tear-proof

- Good mechanical protection

- For heavy-duty work

Nappa leather is distinguished by its soft structure and good dexterity. Gloves made of nappa leather are ideal for all tasks that require dexterity.

Heat protection gloves made of leather combine the positive properties of a natural product with good heat protection. Leather is breathable and comfortable on the skin. It is also very wear-resistant. The protective properties, in particular against splashing metal and heat, make leather gloves suitable for a number of tasks.

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

- Wear-resistant

- Sturdy and tear-proof

- Good mechanical protection

- For heavy-duty work

In the case of split leather, the upper grain layer is removed by splitting. This middle layer of skin is distinguished by its rough velour-like texture. Split leather gloves are resistant to heat and the cold, they are wear-resistant and offer good protection of the hands.